MACHINE FEATURE:

1.HQD 9.0kw air cooling ATC spindle,high precision,long life time,steady working,easy to start up. 2.huge thickness square pipe structure ,well welded, no distortion for whole structure high precision ,and long life time. 3.Taiwan LNC controller system with USB interface,working without connecting with computer during working and easy to control. 4.Software:CAD/CAM designing software such as type3/artcam/castmate/weitai etc. 5.auto oilling system ,easy to operate by pressing one key. 6.seperated control system makes operation easily. 7.Adopt high speed stepper motor and drivers,and two motors for Y axis.max speed is 25mm/min. 8.The vacuum table holds tightly the carving materials which makes operating more reliable and convenient.MACHINE PARAMETERS

| Items | Standard | |

| Model No. | UW-A2030L | |

| Machine body | Thickness tube welding structure | |

| Working area(mm) | X | 2000 |

| Y | 3000 | |

| Z | 350 | |

| Structure | Table size | 2150*3500 |

| table | Vacuum T slot table with powerful vacuum pump | |

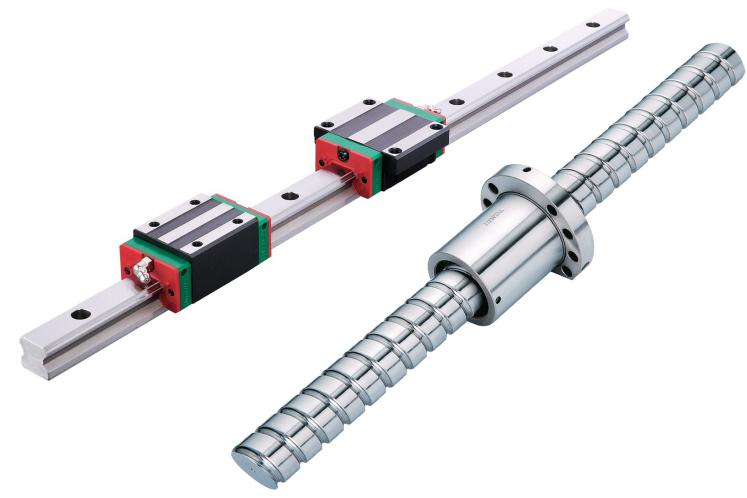

| Transmission system | X | Taiwan HIWIN square guide rail ,TBI ball screw driving |

| Y | Taiwan HIWIN square guide rail ,TBI ball screw driving | |

| Z | Taiwan HIWIN square guide rail ,TBI ball screw driving | |

| Spindle | Power | 9 kw HQD air-cooling ATC spindle |

| Rotating Speed | 18000rpm | |

| Cooling Type | air- cooling/pump | |

| Collet diameter | ER 32 Ø3.175,4,6 8 12.7 | |

| Inverter | DZB200M2005.5L Fuling | |

| About drive systems | X | Leadshine 1500W servo motor and driver+Shimpo reducer |

| Y | Leadshine 1500W servo motor and driver+Shimpo reducer | |

| Z | Leadshine 1500W servo motor and driver+Shimpo reducer | |

| Control System | Taiwan LNC Control system | |

| Data reading mode | line by line | |

| Compatible file formats | G code /PLT/DXF/ENG | |

| Compatible CAD/CAM Softwares | JD pait/Type3 / Artcam / | |

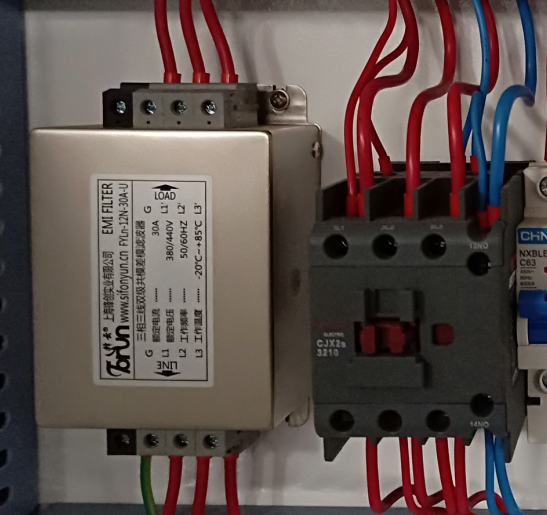

| Working Voltage | 3 phase AC380V/50/60Hz, | |

| Precision | 0.05mm | |

| speed | 30000-45000mm/min | |

| XYZ Positioning Accuracy (MM) | <0.01 | |

| Repetitive Positioning Accuracy(MM) | <0.03 | |

| Gantry Height (From Table) | 250 mm | |

| Gantry made of | Thickness Steel tube | |

| oil-inject lubrication system | Auto Oil system | |

| Power off memory | Function of re-carving after break point and power failure | |

| Accessories | Collets | 3pcs+,(φ3.175, φ4, φ6 φ8 φ12.7) ER 32 |

| Cutter | knives 20pics | |

| Maintenence tools | Tool Box Available | |

| Maintenance | Service can be supplied on line | |

| Guarantee / Warranty | 30 MONTHS | |

| Tech Support | Available | - Online / Phone |

| Damaged / Spoil spare part support | Available | |

| Weight | Net | 2400kg |

| Gross | 2600kg | |

| Delivery Time | 10-15 WORKING DAYS | |

| optional | Side rotary device :diameter:200mm, length:2500mm | |

MAIN CONFIGURATIONS

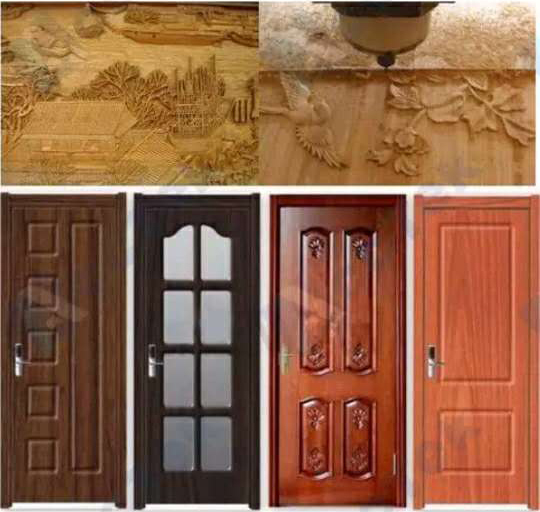

Application

WARRANTY AND SERVICE

SAMPLES

SPARE PARTS

| ||

|

|

|

|

|

|

|

PACKING

1. Engineers availbal to service machinery overseas. 2. 2.5 year guarantee for whole machine. 3. Technical support by phone,e-mail,whatsapp and skype.If you have any problems,we will within 24 hours to solve it. 4. You will be get free training advice towards our machine in our factory. 5. If you need any component of the machine,we will provide the best price for you. 6. Friendly English version manual and operation video CD disk.

1. Engineers availbal to service machinery overseas. 2. 2.5 year guarantee for whole machine. 3. Technical support by phone,e-mail,whatsapp and skype.If you have any problems,we will within 24 hours to solve it. 4. You will be get free training advice towards our machine in our factory. 5. If you need any component of the machine,we will provide the best price for you. 6. Friendly English version manual and operation video CD disk.