Feature Of Machine

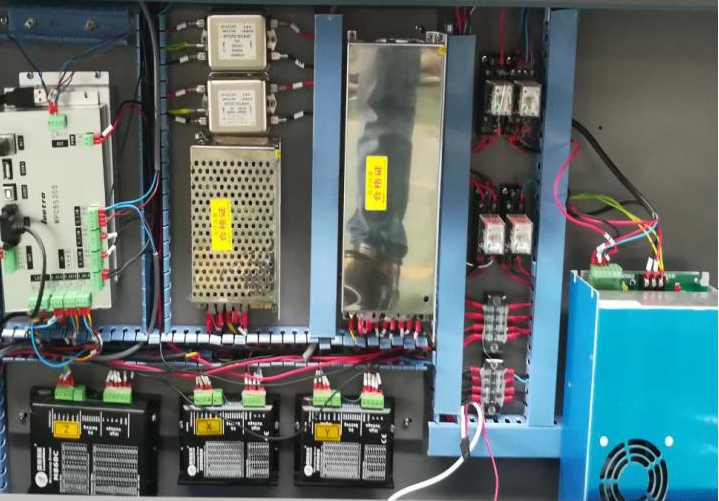

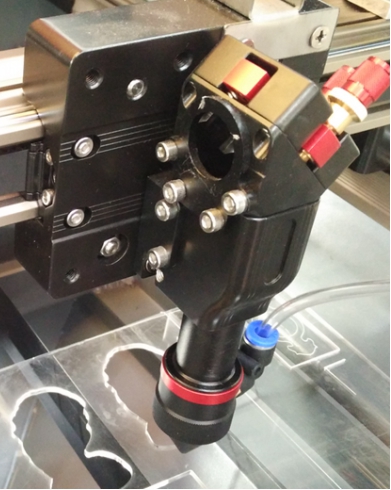

Main Configuration:

Main parts:

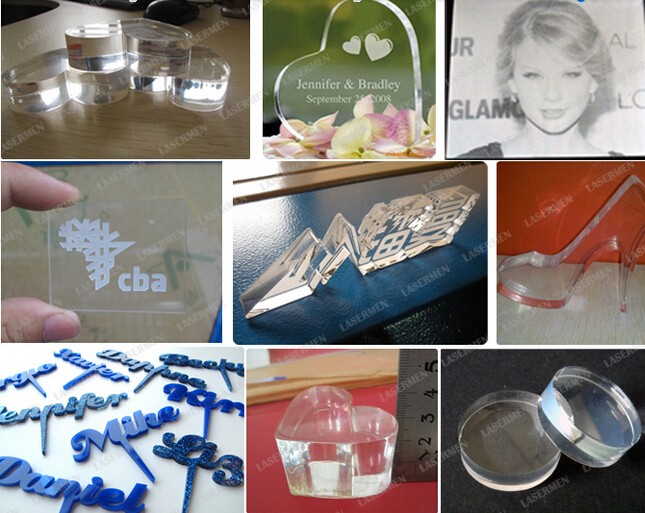

Main samples :

Our service:

1. service before sales: our sales will communicate with you to know your requirements about the cnc router specification and what kind of work you will do, then we will offer our best solution for you. So that it can confirm each customer get their real needed machine.

2. service during production: we will send photos during manufacturing, so customers can know more details about the procession of making their machines and give their suggestions.

3. service before shipping: we will take photos and confirm with customers the specifications of their orders to avoid the mistake of wrong making machines.

4. service after shipping: we will write to customers in time when the machine departs, so customers can make enough preparation for the machine.

5. service after arrival: we will confirm with customers if machine is in good condition, and see if there is any spare part missing.

6. service of teaching: there are some manual and videos about how to use machine. If some customers have further question about it, we have professional technician to help install and teach how to use through Skype, calling, video, mail or remote control, etc.

7. service of warranty: we offer 12 month warranty for whole machine. If any fault of the machine parts within warranty period, we will replace it for free.

8. service in long-term: we hope every customer can use our machine easily and enjoy using it. If customers have any problems of machine in 3 or more years, please contact us freely.

Application

1)Foam processing of automotive stamping dies, casting of wood molds, automotive interiors, engineering plastic materials, and various non-metal processing 2) Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows. 3) Wood mold processing center: Casting wood mold, automotive inspection tool processing, automotive interiors, engineering plastic materials and other non-metallic processing.| Model | UC-6040 | UC-7050 |

| Working Area | 600×400mm | 700×500mm |

| Laser Power | 60W / 80W / 100W / 120W / 150W | |

| Laser Type | Hermetic and Detached Co2 Laser Tube | |

| Engraving Speed | 1-60000mm/min | |

| Cutting Speed | 1-10000mm/min | |

| Repeat Location Accuracy | ± 0.0125mm | |

| Laser Power Controlling | 1-100% Manual Adjustment and Software Controlling | |

| Voltage | 220V(±10%) 50Hz | |

| Cooling Mode | Water Cooling and Protect System | |

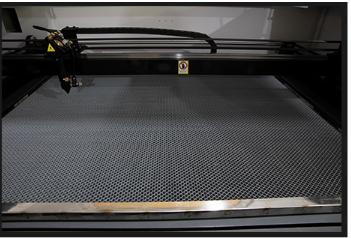

| Cutting Platform | Professional Thickening Strip or Honeycomb Work Table | |

| Controlling Mode | CNC Professional Control System | |

| Support Graphics Formats | BMP, HPGL, JPEG, GIF, TIFF, PCX, TAG, CDR, DWG, DXF Compatible HPG Order To Support DXF, WMF, BMP, DXT | |

| Power Controlling Mode | Laser Energy Combining Movement Control System | |

| Control Software | Original Perfect Laser Engraving & Cutting Software | |

FAQ :