Product description

1. Steel tube lathe bed, low center of gravity, strong bearing capacity, not easy to deformation, stable and reliable operation. 2. Adopt Ncstudio control system , through computer operation, easy and simple to operate. DSP handle offline control is optional. 3. Adopt Taiwan linear guide rail. the bearing of the lead guide rail is face to face, the long time use precision is high. 4. German double nut automatically disappear gap ball screw. 5. Break point and break knife continue engraving function, can engrave at any place as you like. 6. Strong compatibility: compatible various CAD/CAM software like Type3/artcam/castmate/proe/Corelerow/Wentai. 7. Adopt High power frequency changing water cooled spindle, providing excellent cooling effect when carving flinty materials,effectively protect spindle when continuous working for a long time. 8. Axis Y with two spindles, guarantee the cutting strength and engraving precision.Application

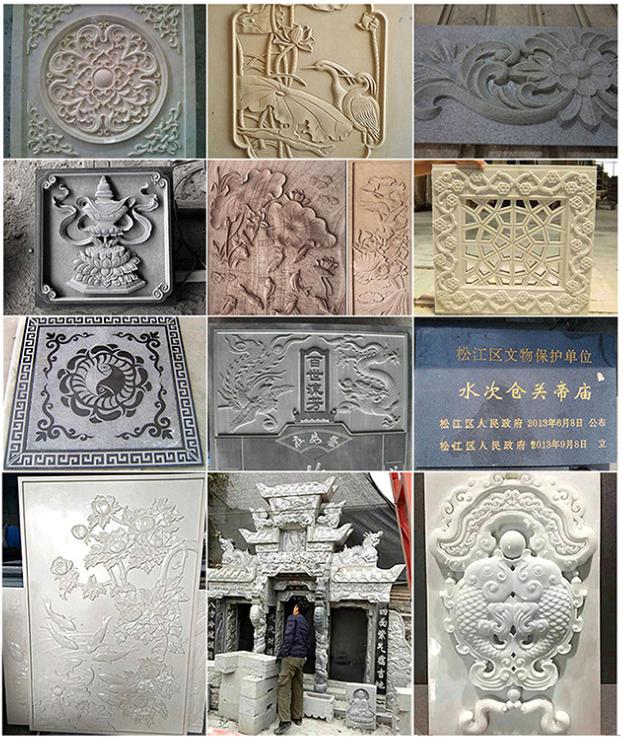

Application Industry: Stone processing engraving, milling, Cutting, mold manufacturing cutting, wood processing cutting, art and craft manufacturing, light box cutting, building mold cutting, indoor decoration cutting, wave board processing cutting, light equipment molding processing cutting, sign and mark manufacturing cutting, acryl board and MDF processing cutting, stamp cutting. Material: Stone, marble, granite, wood, soft metal, rubber, acrylic, plastic and so on.| Wood Processing | Processing density boards ,stiletto for surfing boards ,processing of marbles, cabinet and furniture. |

| Craft | Engraving characters of any language and patterns on gifts and souvenirs, promitive processing and shaping of arttistic crafts and stiletto. |

| Advertisment | Engraving and cutting of various labels and number plate ,marble,ect for aristic effects on materials including marble ,brass ,steel and other metallic material. |

| Moulding | Engraving and cutting of various labels and number plate ,marble,ect for aristic effects on materials including marble ,brass ,steel and other metallic material. |

| Artitechtural models | Engraving fine window ,fencing and wall patterns .ect. |

| Seal | Engraving seals and medal on materials such as buffalo horn ,wood ,ect. |

| Engraving character, number and other pattern on label for products and product directly | Engraving character, number and other pattern on label for products and product directly. |

Main Configuration

| Model | US-1325 |

| Working area: | 1300x2500x300mm |

| Spindle type: | water cooled spindle/air cooled spindle optional |

| Spindle power | 5.5 kw -9.0kw |

| Spindle rotating speed | 18000rpm/24000rmp |

| Power (except spindle power) | 6.8KW (include powers of: motors, drivers, inverters and so on) |

| Power supply: | 3phase 380v/220v, 50 Hz |

| Worktable: | T slot table with water tank |

| Locating precision: | <0.03mm |

| Min shaping character: | Character:3x3mm,letter:1x1mm |

| Operating temperature: | 5°C-40°C |

| Working humidity | 30%-75%(without condensed water) |

| Working precision | ±0.03mm |

| System resolution | ±0.001mm |

| Control configuration: | Mach3/ DSP/ NK260/ Syntec 6MA control system optional |

| Data transfer interface: | USB/PC |

| System environment: | Via computer/ its own panel |

| Spindle cooling way: | Water cooling by water pump/ Air cooling by fan inside spindle |

| Graphic format supported: | G code: *.u00, * mmg, * plt, *.nc |

| Compatible software: | ARTCAM, UCANCAM ,Type3 and other CAD or CAM softwares…. |

| Cutting thickness: | 0-40mm also (depends on different material) |

| Z tool sensor: | yes |

| Positioning pins: | Optional |

| packing | Plywood case (veneer wood case for export) |

| Optional parts | 1 Rotary device model professional for cylinder stone colomn 2. Oil spray cooling system for metal3. Dual-heads or more heads 4. Servo motors (Taiwan brand or Japanese brand) 5. Other custom features |

Our service

Technical Support 1. 24 months quality guaranty for the machine main parts, excluding the consumables, such as water pump, air pump, exhaust fan, etc. shall be changed free of charge when if any problem during the warranty period. 2. Lifetime maintenance free of charge. 3. Free training course at our plant. 4. Manual of video with machine teach the client how to setup, test, align laser, operate and maintain, also supply the specifications setting for speed and power to engrave or cut on various material. 5. Life long tech support by email and web camera. Warranty 2 years for laser machine 10 months for laser tube Delivery Time 1. for small machine, our standard model, generally 7-10 working days 2. for big machine , our standard model, generally 10-15 working days Payment Terms 100% T/T, 30%-45% as deposit, the balance before deliveryMake product display

Main parts

Heavy duty body structure. Can effectively reduce the vibration caused by exercise, thereby improving accuracy.

Heavy duty body structure. Can effectively reduce the vibration caused by exercise, thereby improving accuracy. HIWIN Square guide rail and TBI ball screw. More high accuracy and running stablePowerful Stepper motor Much more powerful and running quickly

HIWIN Square guide rail and TBI ball screw. More high accuracy and running stablePowerful Stepper motor Much more powerful and running quickly Quality Leadshine driver Signal input is more stable, effectively reducing other signal interference

Quality Leadshine driver Signal input is more stable, effectively reducing other signal interference Import WMH rack pinion High-precision rack and pinion, running more smoothly

Import WMH rack pinion High-precision rack and pinion, running more smoothly

Fuling inverter The signal control is more stable, making the spindle run more smoothlyT slot table with PVC and water tank Easy fixed the materials by clamps PVC help protect table Water tank for help collect the waste water

Fuling inverter The signal control is more stable, making the spindle run more smoothlyT slot table with PVC and water tank Easy fixed the materials by clamps PVC help protect table Water tank for help collect the waste water

Ruizhi Auto DSP control system Off line control the machine ,can control the machine easily without computerRotary device (for optional) Can can put the device on the table process on the cylinder and beam. when process on the cylinder ,then put on the table ,when process on the flat ,then remove it is ok. Very convenient and practical.

Ruizhi Auto DSP control system Off line control the machine ,can control the machine easily without computerRotary device (for optional) Can can put the device on the table process on the cylinder and beam. when process on the cylinder ,then put on the table ,when process on the flat ,then remove it is ok. Very convenient and practical. Powerful HQD 5.5kw Spindle More powerful to improve the efficient

Powerful HQD 5.5kw Spindle More powerful to improve the efficient Auto oiling system Automatically oiling for the guide rail and rack pinion

Auto oiling system Automatically oiling for the guide rail and rack pinionFAQ

One-piece tooth box Effectively reduce accuracy problems caused by assembly problems

One-piece tooth box Effectively reduce accuracy problems caused by assembly problems