Feature Of Machine

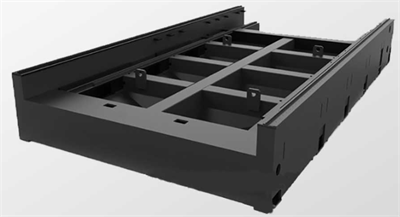

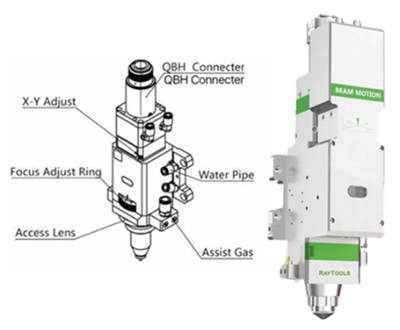

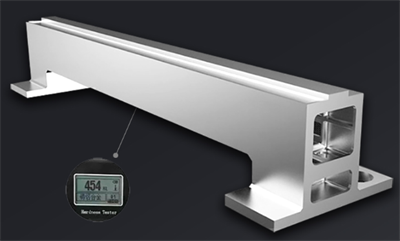

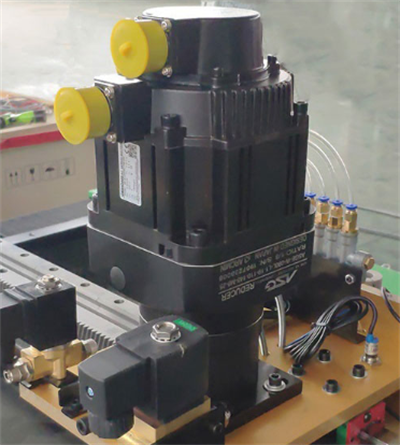

(1). New design, reducing the vibration generated during the high-speed cutting process. (2). Gantry double-drive structure,with imported Germany rack & gear transmission system, which improves the production efficiency. (3). High-performance cast aluminium guide rail, after infinite aalysis ,which accelerates the cicular arc cutting speed. (4). High precision, fast speed, narrow slit, minimum heat affected zone, smooth cut surface and no burr. (5). The laser cutting head does not come into contact with the surface of the material and does not scratch the workpiece. (6). The slit is the narrowest, the heat affected zone is the smallest, the local deformation of the workpiece is very small, and there is no mechanical deformation. (7). It has good processing flexibility, can process any pattern, and can cut pipes and other profiles. (8). Non-deformable cutting can be performed on materials of any hardness such as steel plates, stainless steel, aluminum alloy plates, and hard alloysApplication

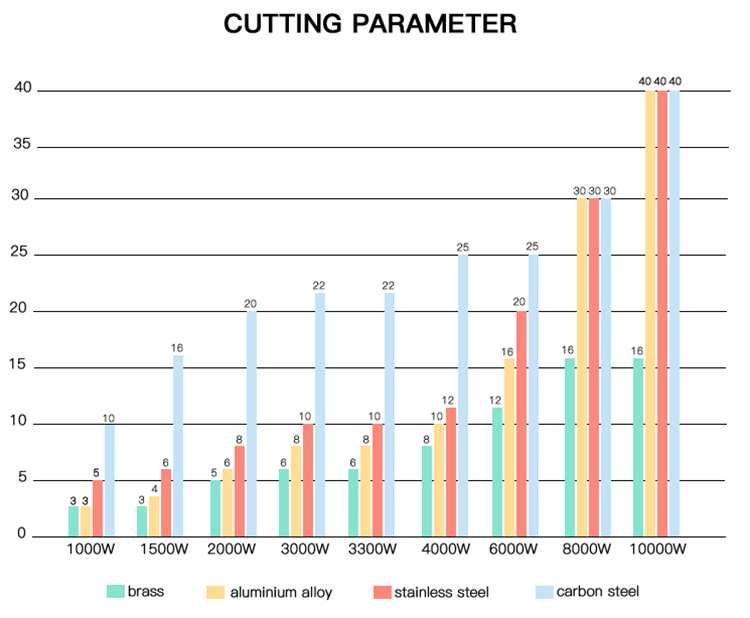

Applicable materials for laser cutting machine for metal Durmapress Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet,Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet,Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc Application Industries Fiber Laser Cutting Machine is widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters,Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & CabinetsProcessing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts,Nameplates, etc Cutting ability specially used in cutting 0.5~14mm carbon steel,0.5~10mm stainless steel,galvanized plate lectro-Galvanized Steel,silicon steel,0.5~3mm aluminium alloy,0.5~2mm brass and red copper etc thin metal sheet (The laser brandcan be customized, power optional from 1000w-6000w )Main Configuration

| Model | UF-C3015L | UF-C1325L |

| Working area | 3000*1500mm | 1300*2500mm |

| Miximum length of pipe(Options) | 3000mm(or)6000mm | |

| Laser type | Fiber laser generator | |

| Laser power(optional) | 1000~4000W | |

| Transmission system | Double serve motor &gantry&rack&pinion | |

| Maximum speed | ±0.03mm/1000mm | |

| Pipe cutting system(optional) | yes | |

| Maximum speed | 60m/min | |

| Maximum accelerated speed | 1.2G | |

| Position accuracy | ±0.03mm/1000mm | |

| Reposition accuracy | ±0.02mm/1000mm | |

| Graphic format supported | CAD,DXF(etc) | |

| Power supply | 380V/50Hz/60Hz | |

Our service

cnc sheet metal fiber laser cutting machine price FAQ

Main parts: 1.Pre-Sales Service: * Inquiry and consulting support. * Sample testing support. * View our Factory. 2.After-Sales Service: *Three-year warranty on the whole machine accessories if the machine parts have any problems,we can change the old machine parts to new ones free. *Exceed three years warranty period if the machine parts have any problems,we can offer new machine parts with cost price and you also should pay all the shipping cost. *We offer 24 hours technical support by call,email. *Our technician can give you remote guide online(Skype/MSN/What's app/viber/Tel/Etc) if you have any question. *Machine has been adjusted before delivery,operation disk is included in the delivery.If there is any other questions,pls kindly tell me. *We have manual instruction and CD (Guiding Videos) for software Installation,operation and machine's using and maintenance. 3.UBO CNC supply free technical training for all customers all over the world until the workers from buyer can operate the machine normally and individually. Mainly training are as follow: *Training for Control software operation. *Training for normatively turning on/off operation of the machine. *Instruction of technical parameters, as well as their setting ranges. *Basic daily cleaning and maintenance for the machine. *Solutions for common hardware problems. *Training for other questions and technical suggestions during daily production. 4.Training can be processed in the following ways: *Workers of customers can come to our factory to get the most professional hand-by-hand training. *We can send engineers to customers' country and do training for workers in customers' target factory.However,tickets and daily consumption like food and accommodation should be afforded by customers. *Remote training through Internet tools like Team-viewer,Skype and other instant communication softwares.

Main parts: 1.Pre-Sales Service: * Inquiry and consulting support. * Sample testing support. * View our Factory. 2.After-Sales Service: *Three-year warranty on the whole machine accessories if the machine parts have any problems,we can change the old machine parts to new ones free. *Exceed three years warranty period if the machine parts have any problems,we can offer new machine parts with cost price and you also should pay all the shipping cost. *We offer 24 hours technical support by call,email. *Our technician can give you remote guide online(Skype/MSN/What's app/viber/Tel/Etc) if you have any question. *Machine has been adjusted before delivery,operation disk is included in the delivery.If there is any other questions,pls kindly tell me. *We have manual instruction and CD (Guiding Videos) for software Installation,operation and machine's using and maintenance. 3.UBO CNC supply free technical training for all customers all over the world until the workers from buyer can operate the machine normally and individually. Mainly training are as follow: *Training for Control software operation. *Training for normatively turning on/off operation of the machine. *Instruction of technical parameters, as well as their setting ranges. *Basic daily cleaning and maintenance for the machine. *Solutions for common hardware problems. *Training for other questions and technical suggestions during daily production. 4.Training can be processed in the following ways: *Workers of customers can come to our factory to get the most professional hand-by-hand training. *We can send engineers to customers' country and do training for workers in customers' target factory.However,tickets and daily consumption like food and accommodation should be afforded by customers. *Remote training through Internet tools like Team-viewer,Skype and other instant communication softwares.